Fat Rolls and Silicone

In my last post I mentioned the first roller in my AMS was not doing a great job at gripping the filament spool. I decided I wanted to do this AMS ultimate front rollers mod, at least on the first slot for now to make sure it works.

The mod calls for silicone tubing and the description includes a link to some on Amazon that’s supposed to work. My silicone tubing arrived today, so I was ready to print the rest of the parts.

From what I gathered, the mod has two variants that determine which parts you need to print: rollers for the Hydra PRO or the Bambu AMS. I didn’t understand what the difference between the two was exactly, and neither seemed totally appropriate for me since I did a standard Hydra AMS (not a Hydra PRO) mod. However, the implication of this is that the Hydra PRO has different rollers than the Bambu AMS, and since my mod allowed me to simply drop in the stock rollers, it naturally would make the most sense that I’d need the stock Bambu parts.

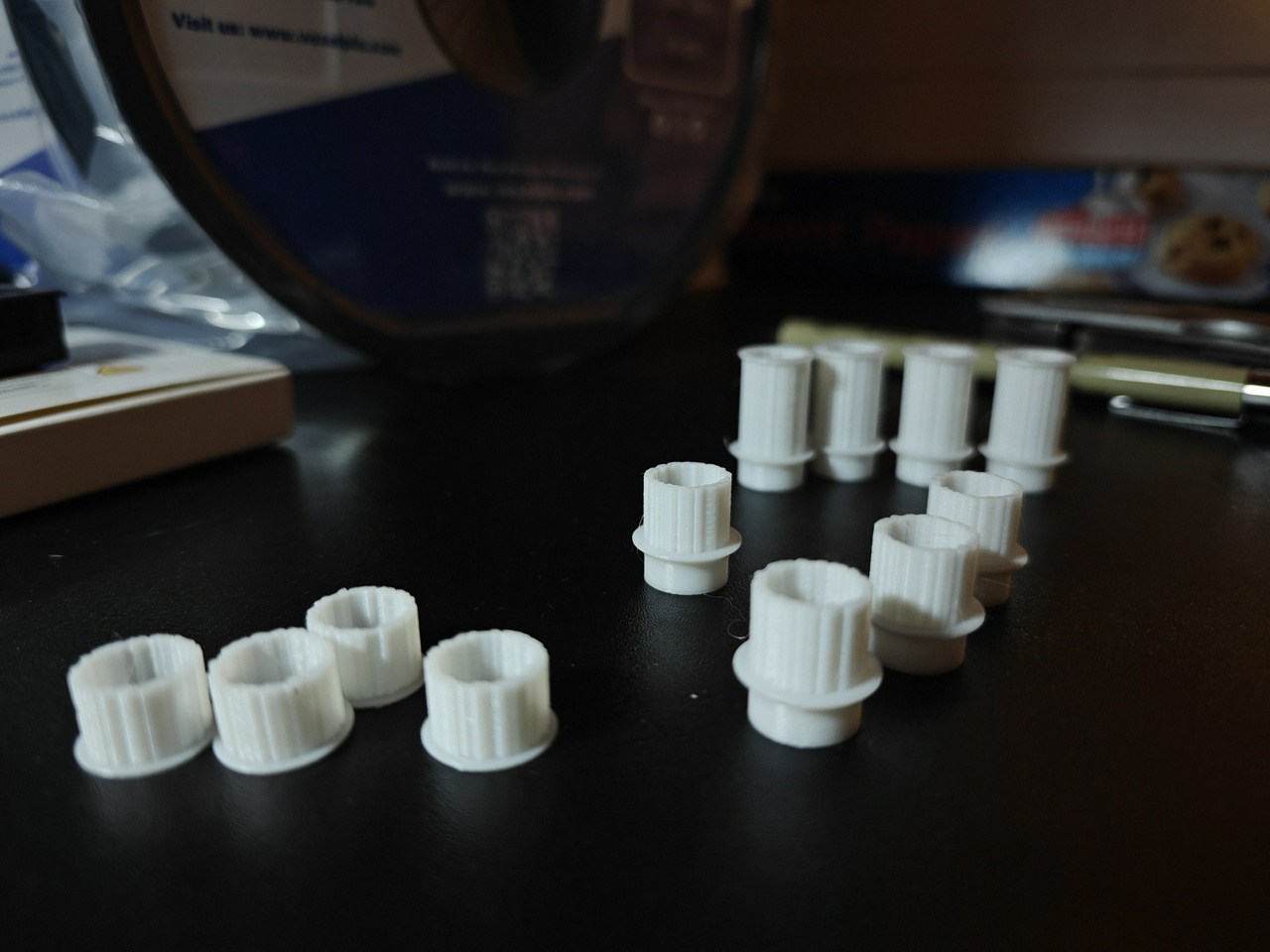

I printed four of everything. The instructions aren’t great. These parts aren’t referred to by their label in the instructions, describe only two of the parts, and the pictures used show what look like two completely different parts being used between steps. What they did call for that I understood was the roller would need the rubber removed, so I got to work on that.

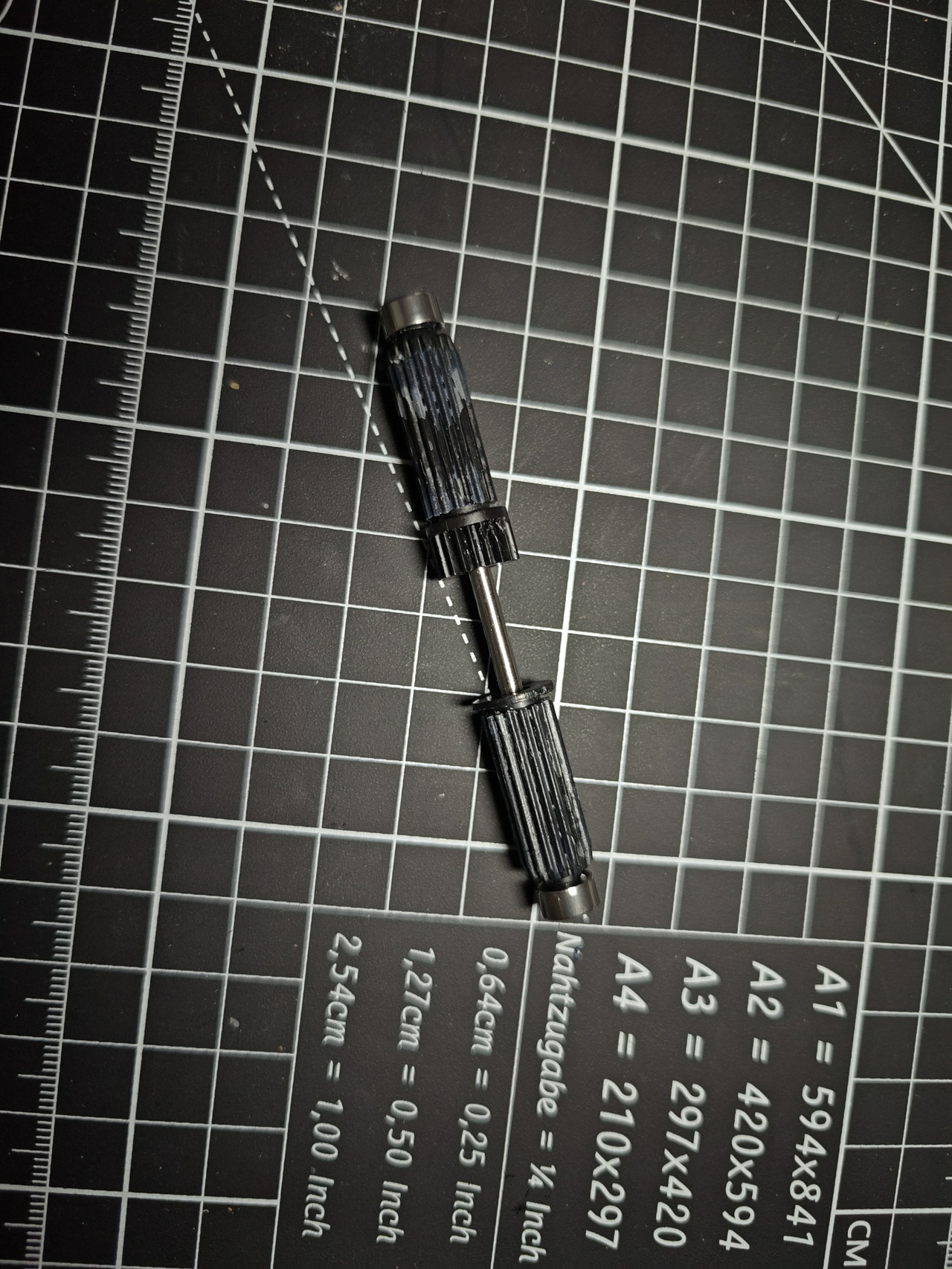

In doing this, I figured out what the issue was with my first roller that made it act up more than the other rollers. See how the rubber grips are on opposite ends of the roller? The rubber piece that isn’t connected to the gear wasn’t staying put. It would slide along the metal rod and could rotate around it. So essentially, any time the gear spun this roller, the roller was only able to rotate the filament from one side, and this often meant that it didn’t have the grip needed to rotate a roll that was nearly full. This also explains why moving the rear roller into the front slot fixed the issue. The roll was pushed into the rubber, which would cause it to push into the rod, which helped it grip the rod better, which finally gave the roller what it needed to turn the spool.

I went ahead and popped the rubber off, which exposed two plastic cores covered in flaky glue residue that easily peeled off in sheets when scraped with a Flathead screwdriver.

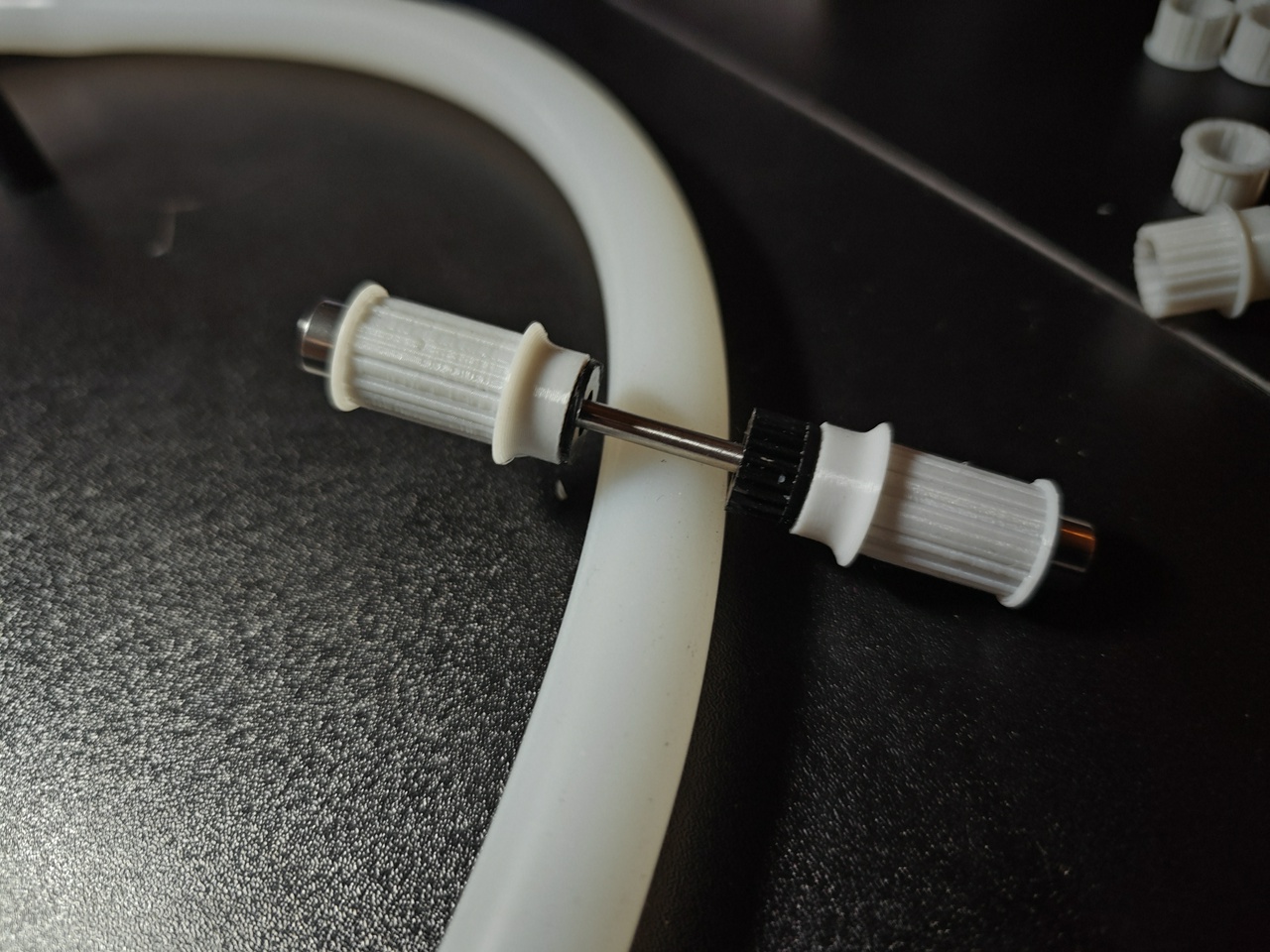

From here, I determined that I needed two of the wider parts I had printed; the other two parts could be pushed together to essentially mimic this one part. I’m assuming this was done so supports wouldn’t be needed (I’m not entirely convinced they were needed, but my slicer did default to adding some and I don’t usually argue with it about that if all I’m saving is 10 minutes of print time). In any case, I put some superglue on the innards and slid the printed parts on.

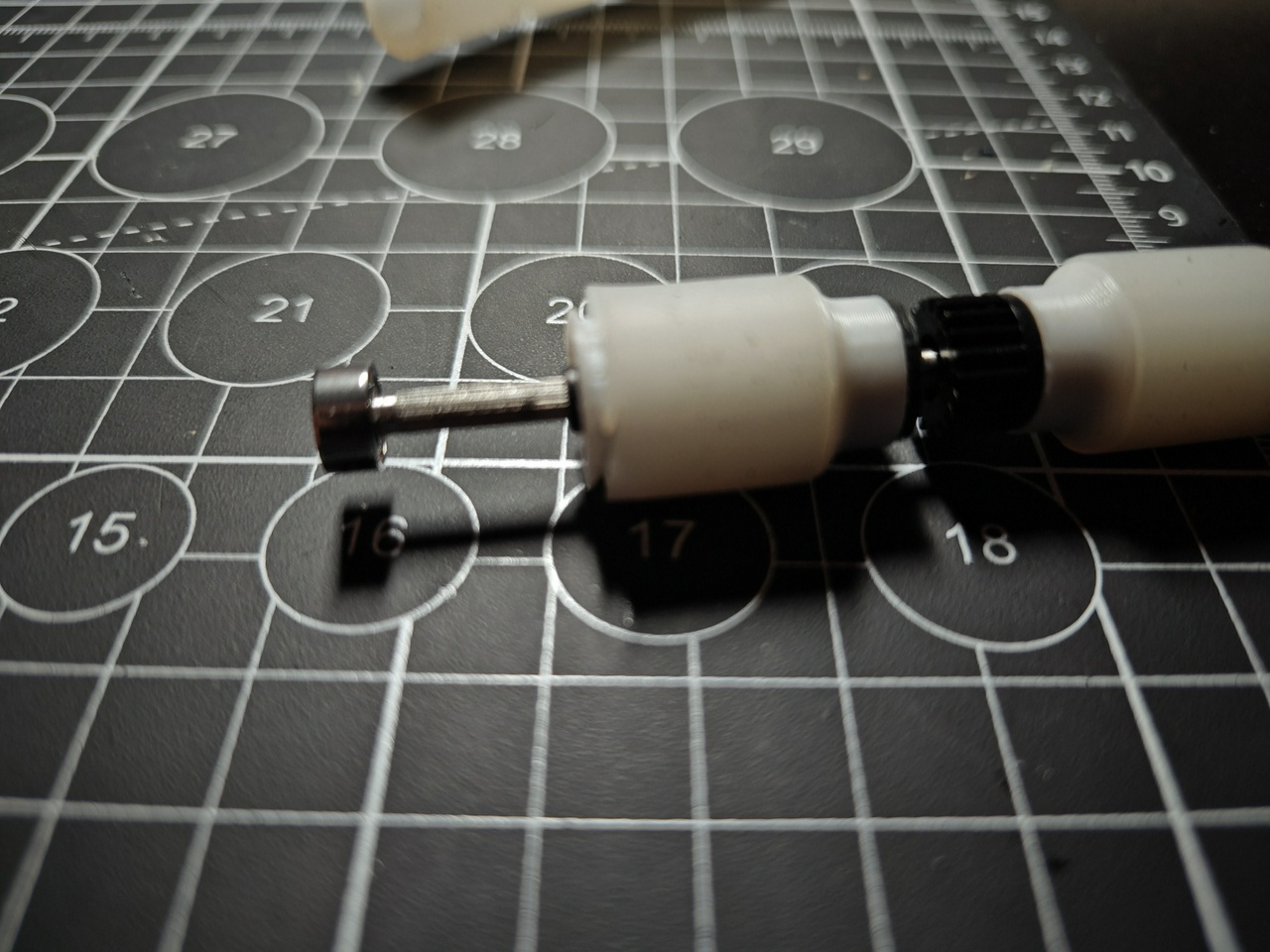

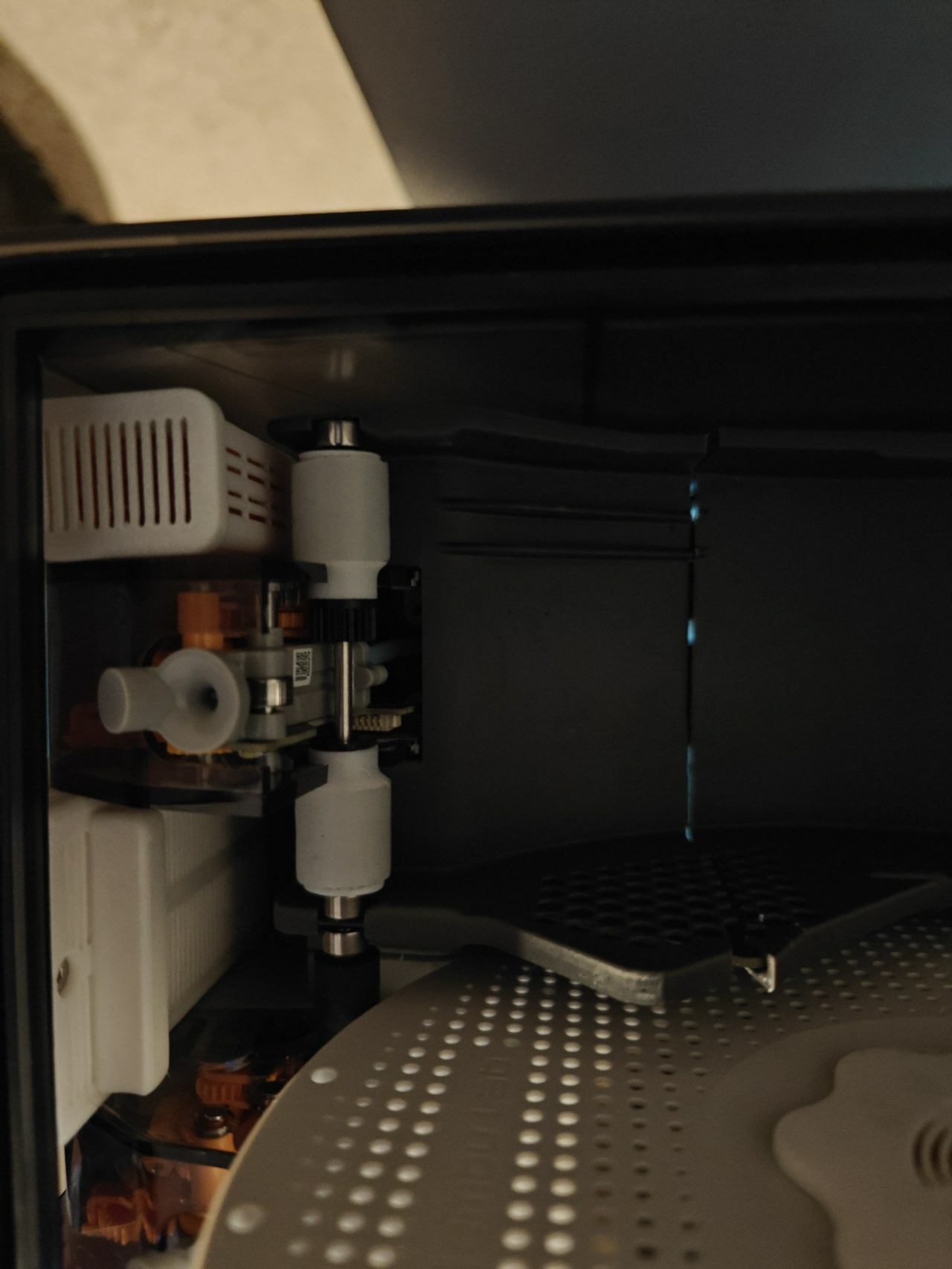

I let the glue dry for a little bit, and finally it was time to put on the silicone tubes. They’re kind of a pain. They have just a tiny bit of stretch, so I had to very slowly work this thing onto the ends and then cut it down to size once it was in place by rotating it underneath an X-acto knife. Not perfectly flush, but good enough. This was also the point where I addressed the one half of the roller not being affixed to the metal rod with some more superglue. While I did that, I made sure to rotate them a little to spread it thin so it wouldn’t get a glob of glue onto the bearings on the end of the roller. Here’s a picture of the silicone tubing on the roller, and the exposed metal rod before gluing the piece in place.

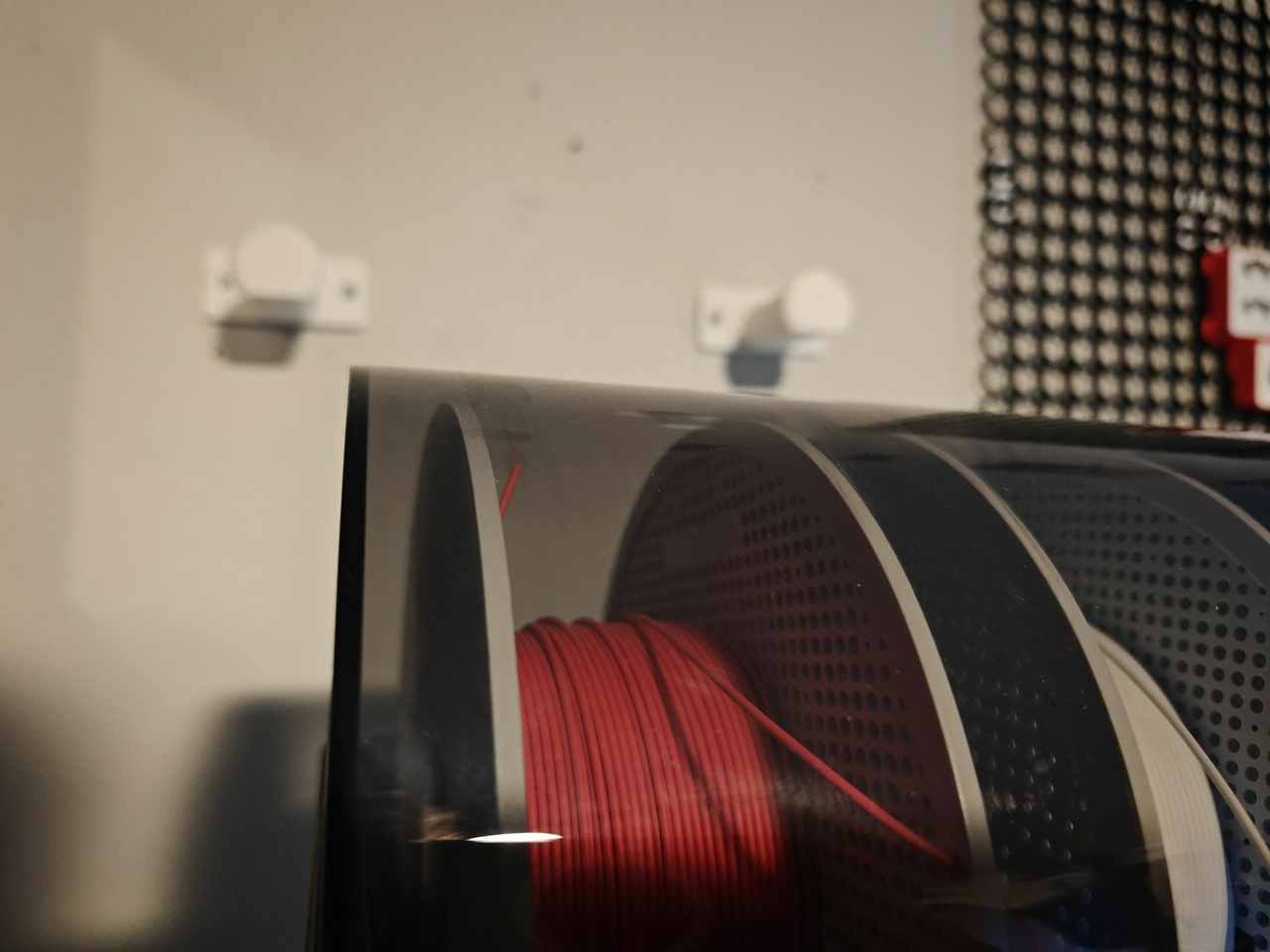

Once the glue was dry, it was time to pop the roller into place. It’s a little harder to work into the mounts in this configuration, but never to the point where I was worried I might have done something wrong or could potentially break something. Once it was in place, I set some filament on top and just rolled it around. It had to be seated more precisely than before, but once it was right the roll turned more confidently than ever.

One concern that some people had pointed out in the comments for the mod was that the suggested silicone tubes were so thick that the reusable Bambu spools would bump the top of the AMS. I lowered the lid to check for this on both a Bambu spool and a VoxelPLA spool. Both managed just fine.

Eventually I’m going to be repeating the mod for the other three rollers, but since they’ve been relatively problem-free it’s not high-priority.

What is high-priority is the Multibin drawers I mentioned in my last post. I’ll take that opportunity to take stock of the screws I have laying around and the ones that it would make sense to load up on, since that’s going to determine what sort of layout makes the most sense for organizing them.