Case grounding

For jacks, most manufacturers these days use chrome ferrule PCB mounted Neutrik NMJ4HCD2 (Mono-switched) or NMJ6HCD2 (stereo-switched). The reason these are so widely used is that the ferrule screws in from the outside, so the fully assembled circuit board just drops into the case.

But we also want the case grounded to avoid static charge buildup, and that jack washer is plastic, thus insulating. And of course we are using center-negative power, so the power jacks are also not grounding the case. What to do?

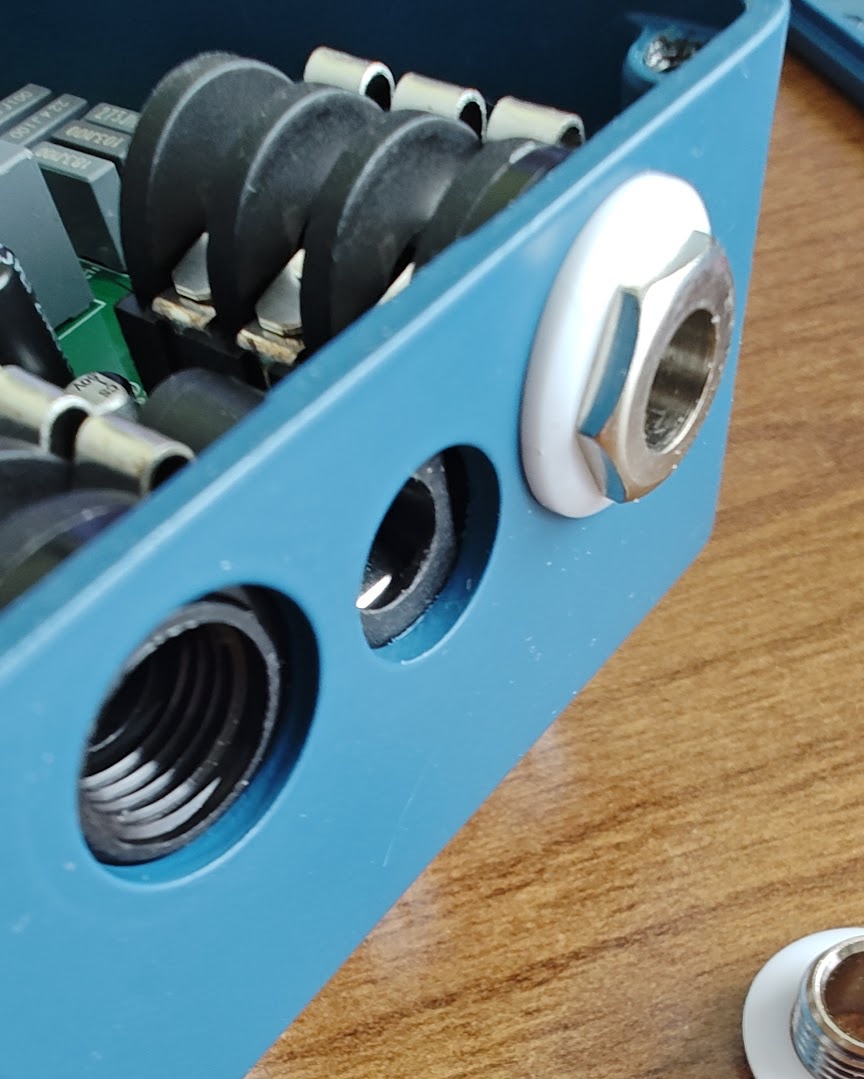

MXR just replaces the nice looking washer with a lock washer on both input and output and calls it a day:

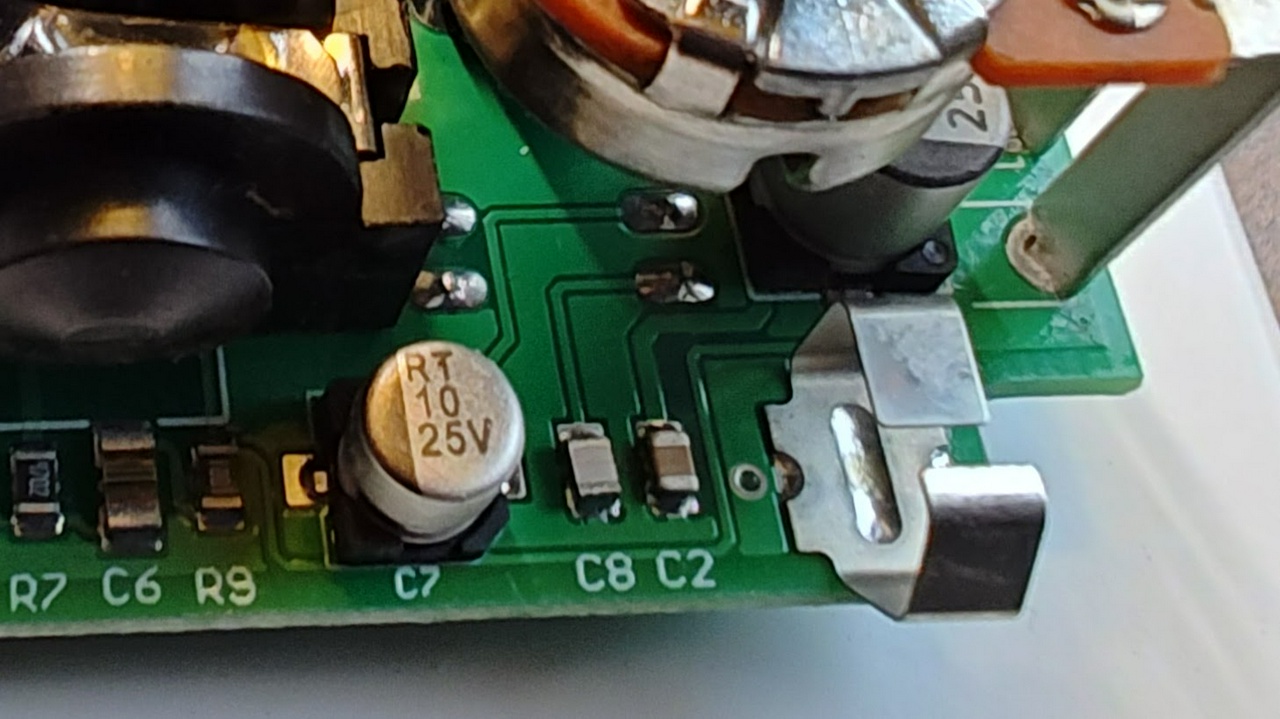

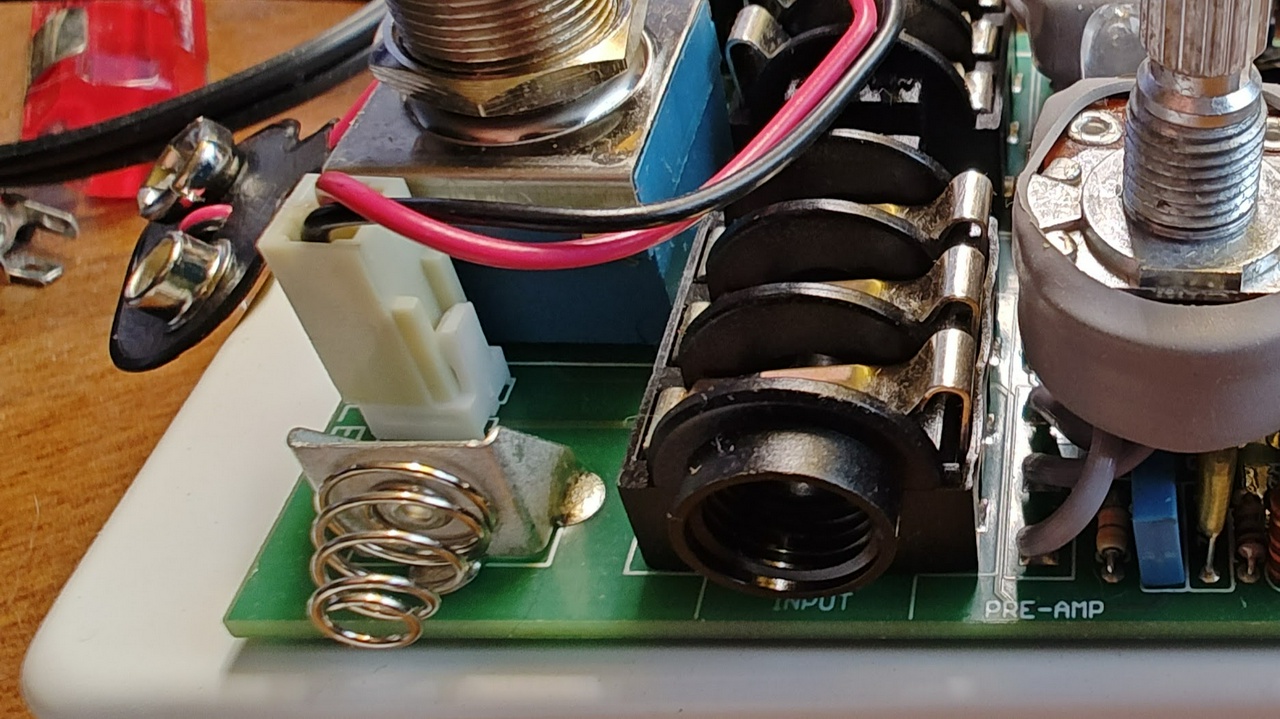

Keeley uses Harwin SMT Multi-dimensional Spring Contacts:

I believe that’s a S1941-46R, surface mount, 7.3mm tall with 1mm deflection. Most of Harwin’s spring contacts are vertical only, the S19x1-46R series is the only horizontal contact I can find.

I also found a Reddit thread that recommends pogo pins for vertical contact.

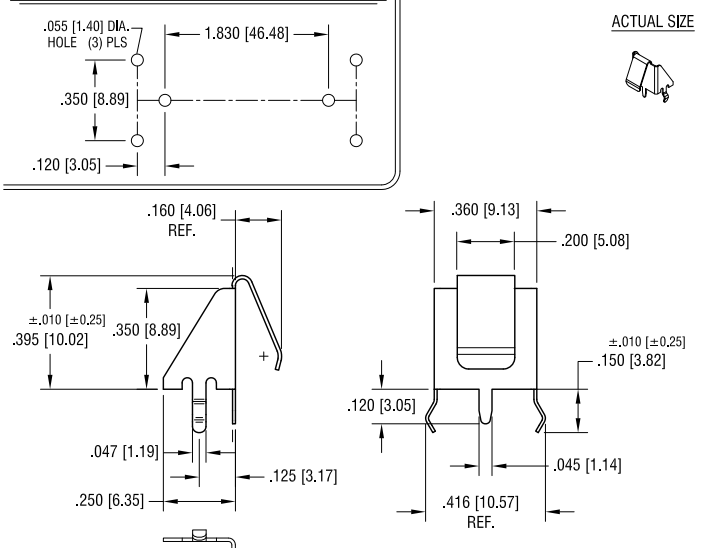

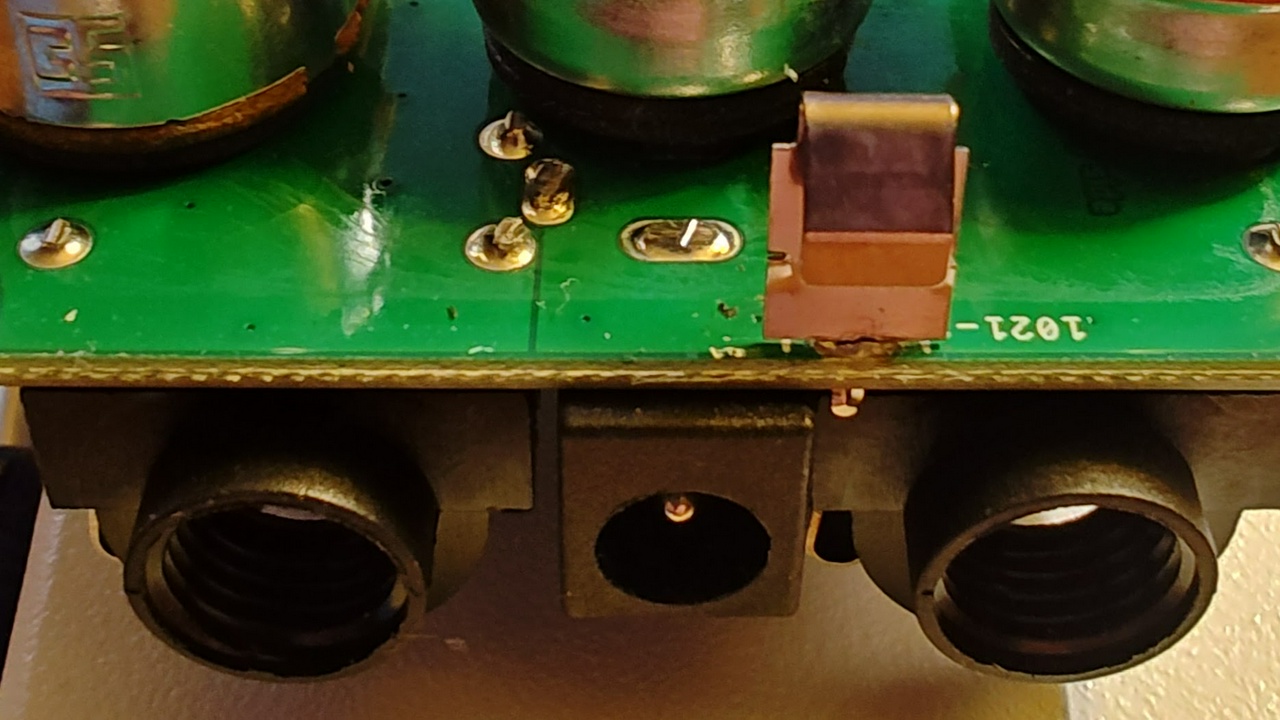

The other option I’ve found for horizontal contact is Keystone battery clips. Wampler uses what I believe is a Keystone 1021-1

Catalinbread is using the Keystone 629 battery contact, I think

One I found that looks particularly appealing is Keystone 591: